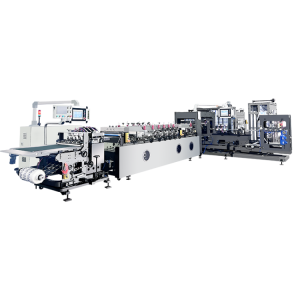

NCA600SZL THREE-SIDE SEAL,STAND-UP, ZIPPER BAG MAKING MACHINE

Usage

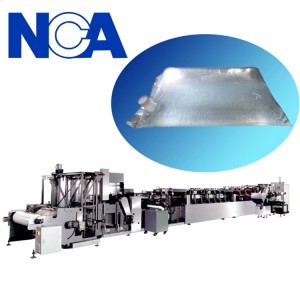

l.This machine is used for making three-side sealing and stand-up pouch from the plastic laminated film.

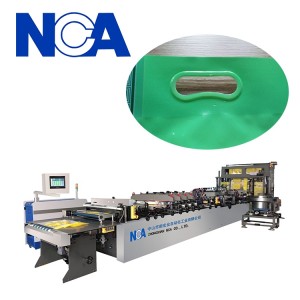

2.It can be widely suitable for making 3-side sealing bag (2 bags feeding), stand-up pouch (double bags feeding), zipper bag (double bags feeding), stand-up zipper bag (double bags feeding).

Advantage

1.Multi-functional bag making machine

2.Applicable bag type:four-sided sealing bag,Soft handbag

3.Speed: 150pcs / min

Machine technique parameters

| Model | NCA600SZL |

| Roll size | (Max width ): 1220mm;(Max diameter ): φ800mm |

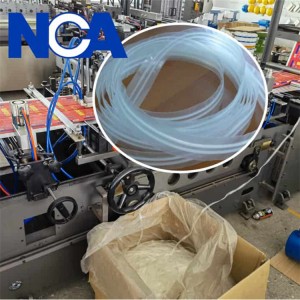

| Stand-up pouchauxiliary material | (Max width): 150mm(Max diameter): φ600mm |

| Bag-making specification | (Width ): 80-320mm (Length ): 80-600mm( Bottom gusset): 20-70 mm |

| If bag width over 320mm, need to use multiple conveying | |

| Bag-making speed &Suitable bag type | (3-side seal bag): 80-150parts/min(zipper bag ): 80-100 parts /min(Stand-up pouch): 100 parts /min |

| Unwinding way | Horizontal unwinding spindle, pneumatic locking. |

| Power | AC 380V, 50HZ, 78KW |

| Compressed air | 0.5-0.7Mpa |

| Cooling water | 8-10L/min |

| Dimension | (L×W×H) 12700×2500×2000mm |

| Weight | 9000KG |

Working process of this machine

The machine starts from unwinding, in turn are magnetic powder brake, dancer arm roller tension adjusting, cutting, rectifying, double layers coinciding, zipper sealing(hot/cold), servo drag, vertical sealing(hot/cold), servo drag, cross hot sealing, cross hot sealing, cross cold sealing, bag spare side cutting, color code track, servo traction, cutting off,

products unloading table.