NCA600SJA Automatic Bag Making and Spout-welding Machine

Usage

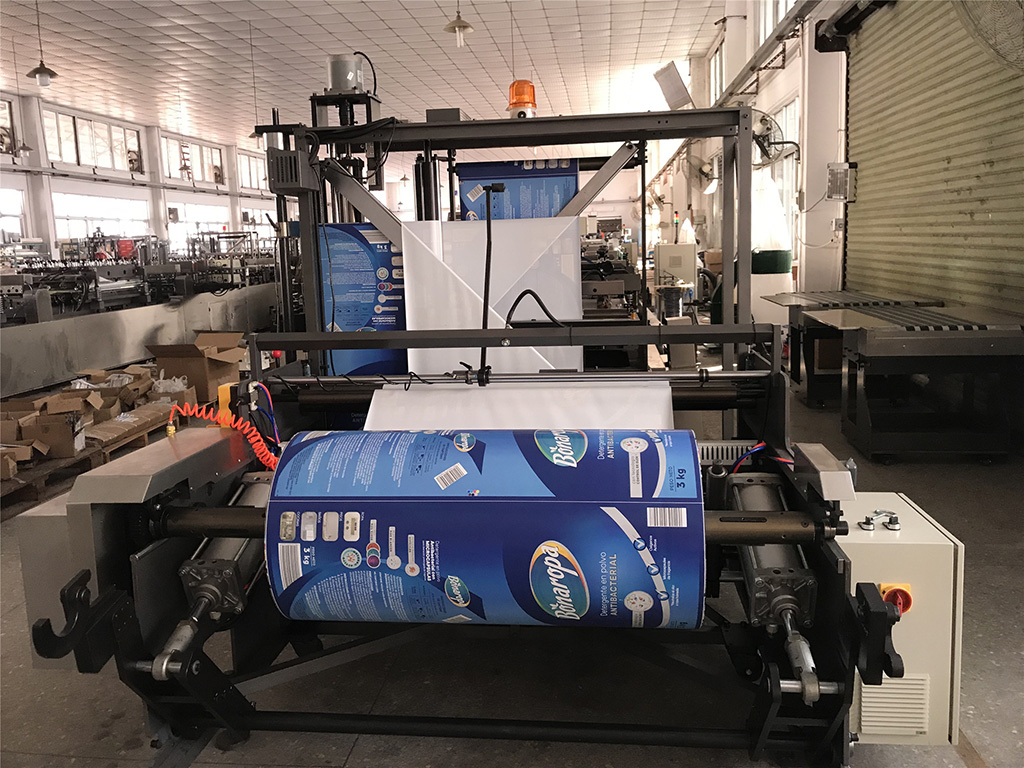

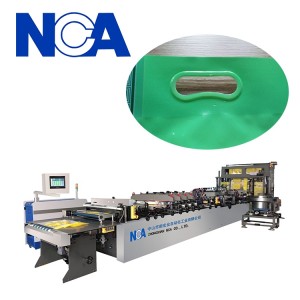

l.The machine is used to make bags, cut an angle and weld plastic spouts on the cut automatically. The bag-making and spout-welding can be done at the same time.

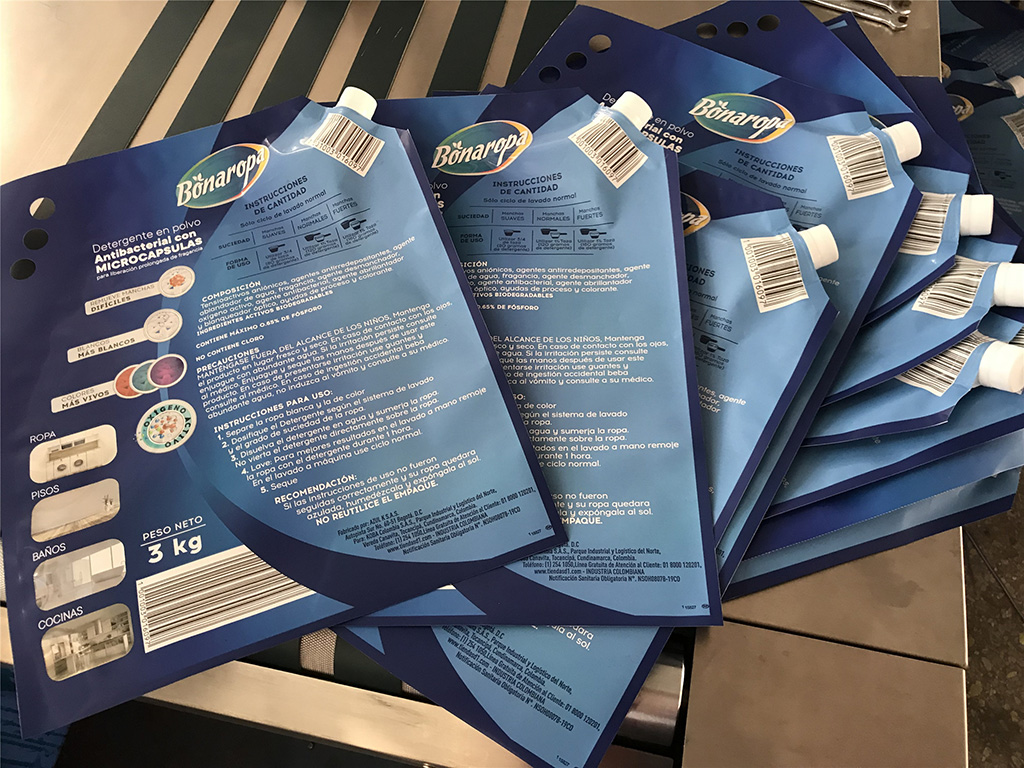

2.It is suitable for the large pouches of drinks, sauce, washing liquid, hand washing liquid and sugar powder etc.

Advantage

1.Capacity:25-30pcs/min

2.Bag making, welding nozzle integrated machine.

3.It is suitable for the large pouches of 3~5L.

Working principle and process

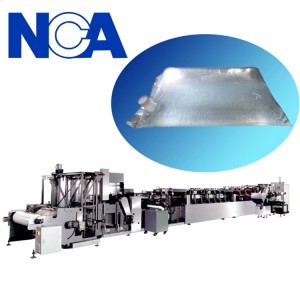

1.This machine is for producing three side seal bag with spout.

2.This machine is for making three-side sealing bag and welding spout (one lance)

and three side seal bag(two lances).

3.Install the film reel with air shaft; put it on the film reel frame. Pull the film by hand, put it under the last servo pulling roller, adjusting, press the RUN button, machine begin to work. The machine starts from unwinding, in turns are tension control, rectifying, cutting from film center, double layers coinciding, dancer arm roller tension adjusting, vertical sealing, servo drive, cross sealing, handle punching, angle cutting, spout feed and spot weld, spout hot welding, spout cold sealing, pouch edge cutting, color code tracking, servo traction, cutting off etc. Whole processes are automatically.

Machine technique parameters

| 1 | Film material | BOPP、CPP、PET、PE、NYLON etc. Various laminated films. |

| 2 | Capacity: | 25-35parts/min |

| 3 | Material thickness | Max 440×320mm |

| 4 | Spout type | one kind short spout.Max inside diameter 22mm. |

| 5 | (Speed for spout pouch, specific speed according to pouch size and material) | |

| 6 | Pouch size:(L×W) | Max 450×320mm |

| 7 | Total power | About 50KW |

| 8 | Power voltage | AC380V,50HZ, 3P |

| 9 | Air pressure: | 0.5-0.7Mpa |

| 10 | Cooling water: | 10L/min |

| 11 | Machine working table height: | 950mm |

| handle operation height 850mm | ||

| 12 | Machine dimension(MAX): | L×W×H: 14000×2600×1960mm |

| 13 | Machine weight: | about 7000KG |

| 14 | Machine color: | Gray (wallboard)/ stainless steel (guard board) |