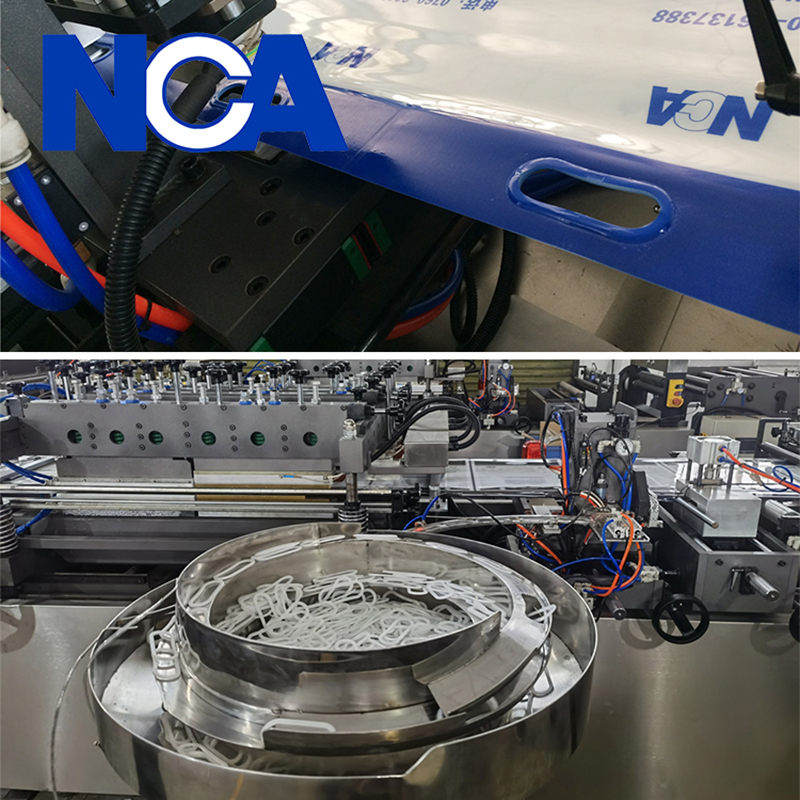

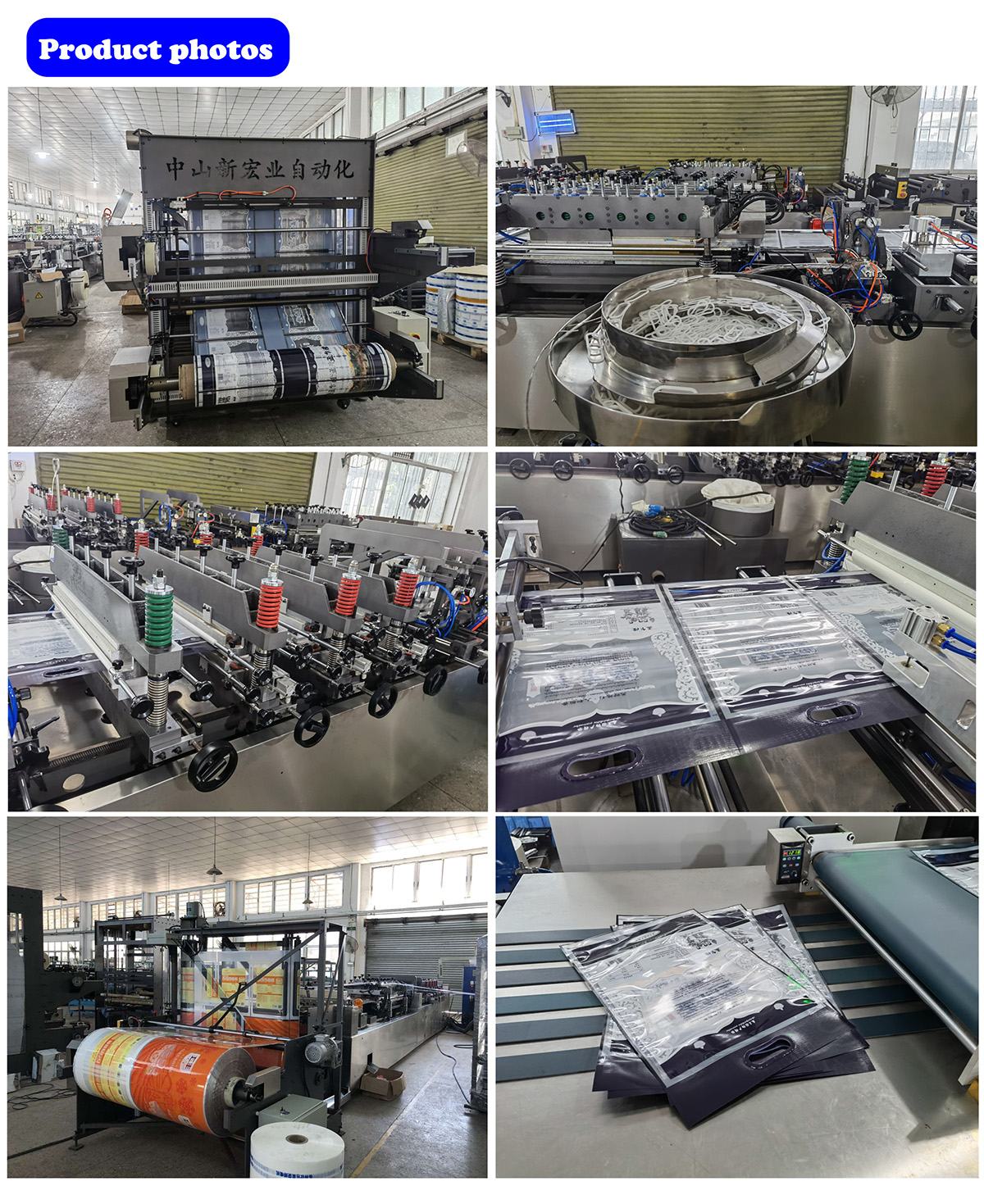

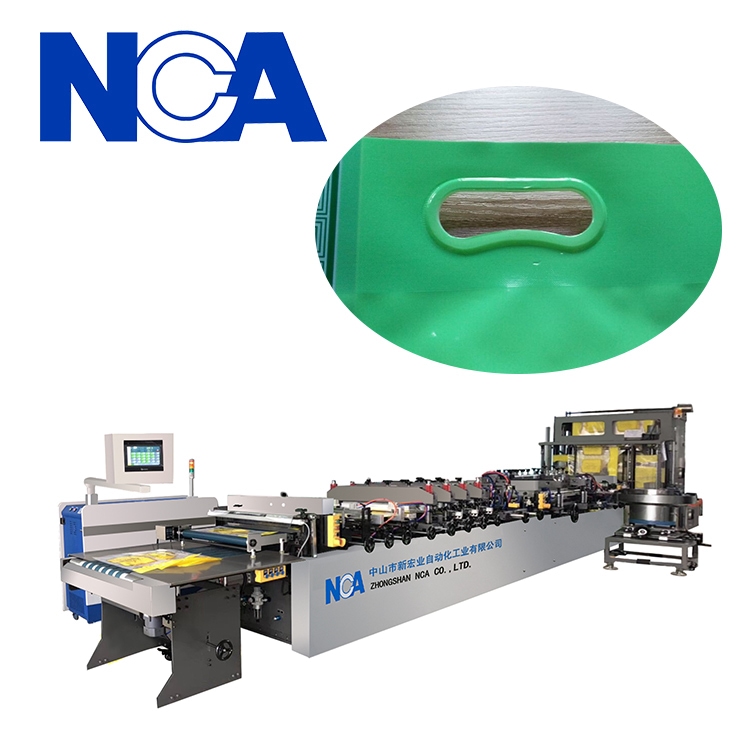

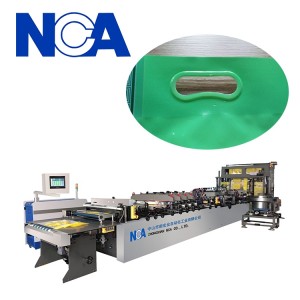

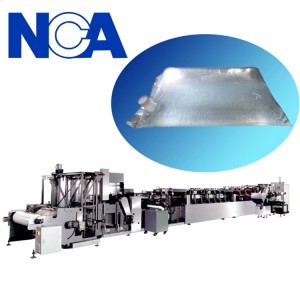

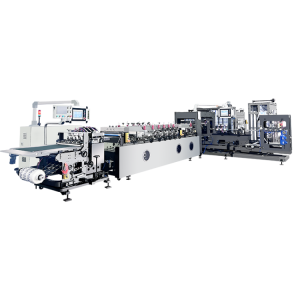

NCA600SHW Three-side Seal Bag Making and Handle Welding Machine

Usage

l.This machine is used to make packaging bags of various laminated films with plastic spouts, the bag making and the spout sealing are done at the same time.

2.The products are widely used for high-capacity packaging of food, such as red wine, edible oil, fruit juice, chocolate plasma, drinking water, soy sauce etc; also used for hand washing liquid, washing liquid, disinfectant liquid, printing ink and other liquid daily chemicals etc.

Advantage

1.This machine is used to make packaging bags of various laminated films.

2.Through the optional auxiliary device, it can be widely suitable for making three-side sealing bag and three-side bag with welded handle.

List of Key Components

|

1. |

PLC control module |

Panasonic Japan |

|

2. |

Servo motor |

Panasonic Japan |

|

3. |

Film unwinding constant tension, AUTO rectifying |

|

|

4. |

Speed reducer |

Planetary China |

|

5. |

Color mark sensor |

Italy |

|

6. |

Cylinder |

AirTAC China |

|

7. |

10.4’ touch screen |

WEINVIEW, Taiwan |

|

8. |

Machine control system |

Hangzhou Sotry, China |

Machine technique parameters

| 1. | Film material | BOPP、CPP、PET、PE、NYLON etc. Various laminated films. |

| 1. | Capacity: | Three-side seal with handle bag: 20-25parts/min |

| 2. | Max film reel unwinding speed: | 36m/min (Machine designing speed) |

| 3. | Bag making error | length and width : ±1mm. |

| 4. | (Actual capacity is according to the bag length, film material and hot sealing efficiency.) | |

| 5.. | Film reel size: | Main film:Max φ800×1220mm(width), inner hole:3′ |

| Gusset film: Max φ600×150mm,inner, hole:3′ air shaft | ||

| 6. | Pouch size: | Bag length: Max580mm Bag width: Max420mm,(over 420 mm need the multiple conveying). |

| 7. | Total power | About 52KW |

| 8 | Power voltage | AC Three phase 380V,50HZ |

| 9 | Air pressure: | 0.5-0.7Mpa |

| 10 | Cooling water: | 10L/min |

| 11 | Machine working table height: | 950mm |

| handle operation height 850mm | ||

| 12. | Machine dimension(MAX): | L×W×H: 11000mm×3000mm×2000mm |

| 13. | Machine weight: | about 6000KG |

| 14 | Machine color: | Gray (wallboard)/ stainless steel (guard board) |