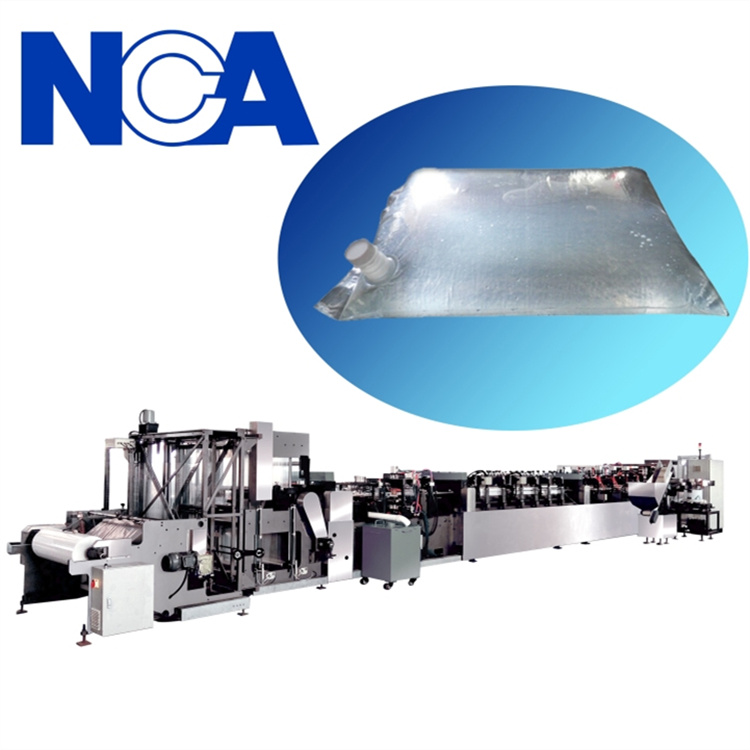

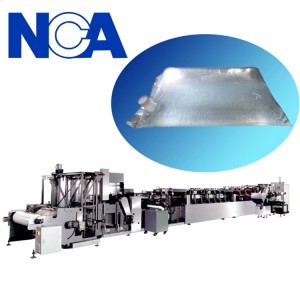

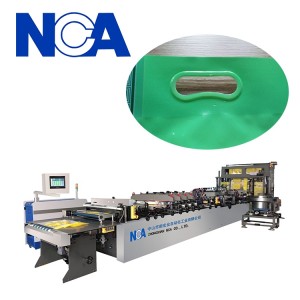

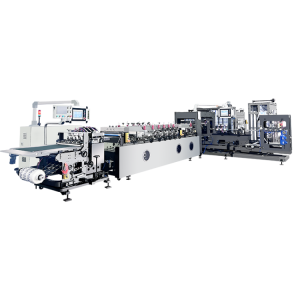

NCA600BIB Automatic Bag-in-box Production Line

Usage

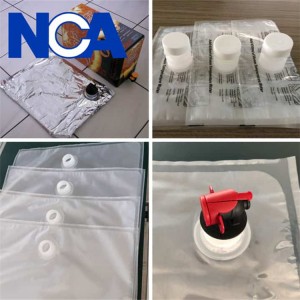

l.This machine is used to make packaging bags of various laminated films with plastic spouts, the bag making and the spout sealing are done at the same time.

2.The products are widely used for high-capacity packaging of food, such as red wine, edible oil, fruit juice, chocolate plasma, drinking water, soy sauce etc; also used for hand washing liquid, washing liquid, disinfectant liquid, printing ink and other liquid daily chemicals etc.

Advantage

1.Capacity: :25-30pcs/min

2.Fully automatic, save labor

3.The bag-making welding nozzle on line

Working process

Double film reels unwinding, film feeding, rectifying, film composite, hole punching, spout feed, spout sealing, bag making, cap pressing cutting and etc. The working process is reasonable, finish it automatically.

Machine technique parameters

| 1 | Film material | Plastic laminated film |

| 2 | Capacity: | 25-30pcs/min (5-22 liter) |

| 3 | Material thickness | 0.06~0.18mm |

| 4 | Spout type | according to one kind of spout supplied |

| 5 | (Speed for spout pouch, specific speed according to pouch size and material) | |

| 6 | Pouch size:(L×W) | Max680×530mm Min200×200mm |

| 7 | Total power | About 60KW |

| 8 | Power voltage | AC380V,50HZ, 3P |

| 9 | Air pressure: | 0.5-0.7Mpa |

| 10 | Cooling water: | 10L/min |

| 11 | Machine working table height: | 1050mm |

| handle operation height 850mm | ||

| 12 | Machine dimension(MAX): | L×W×H: 14300×6200×1950mm |

| 13 | Machine weight: | about 8500KG |

| 14 | Machine color: | Gray (wallboard)/ stainless steel (guard board) |