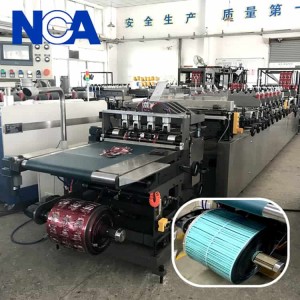

NCA6001C Die cutting machine for flexible bag making machine

Usage

1.Die cutting machine is one auxiliary device for flexible bag making machine, to produce three-side irregular bag and stand-up irregular pouch.

2.The device can be connected with the bag making machine, the bags can be punched in line, after punching, the wasted material can be wound automatically.

3.The final products can be packed and no need to post processing. In order to avoid from re-punching by manual and reduce the wastes of the manpower, resource and time.

Advantage

1.Full frame is casting, high precision,.

2.Widened table, can be lifted.

3.Speed:Max150part/min

4.Pneumatic locks cutter, fast to change.

Machine technique parameters

Die cutting machine is one auxiliary device for flexible bag making machine, to produce three-side irregular bag and stand-up irregular pouch. The device can be connected with the bag making machine, the bags can be punched in line, after punching, the wasted material can be wound automatically. The final products can be packed and no need to post processing. In order to avoid from re-punching by manual and reduce the wastes of the manpower, resource and time.

Machine technique parameters

| 1 | Film material | PET/PE.PET/CPP.BOPP/PE.PET/AL/NY/PE.PET/NY/PE etc laminated material |

| 2 | Material width | 600mm |

| 3 | Capacity: | 60~150pcs/min (according to the step length of bag) |

| 4 | Max punching square | MAX 580×300mm |

| 5 | Die cutter installing size | 600×320mm |

| 6 | Bag type | Three-side shaped bag, stand up shaped pouch, zipper bag etc |

| 7 | Total power | 3KW |

| 8 | Power voltage | AC380V,50HZ, 3P |

| 9 | Machine dimension(MAX): | L×W×H: 1500×1400×1200mm |

| 10 | Machine weight: | about 900KG |

| 11 | Wasted edge | Two side edges (film flowing direction) leave at least 5mm, wasted edge between two bags leave at least 4mm. |