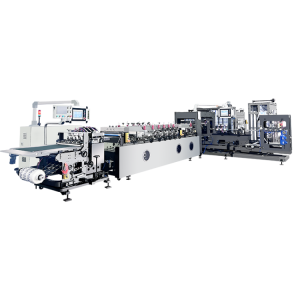

NCA300SJA Automatic Bag Making and Spout-welding Machine

Usage

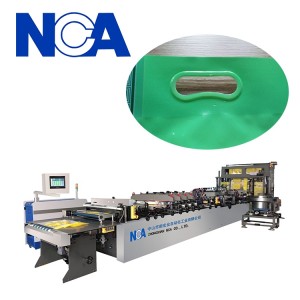

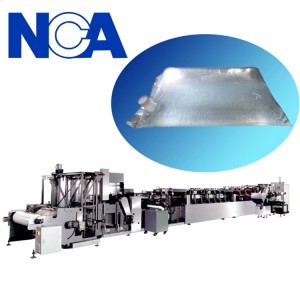

1.The machine is used for making three-side sealing bag or stand-up bag with spout from the plastic laminated film.

2.The machine starts from unwinding, in turn are magnetic powder brake, dancer arm roller tension adjusting, cutting, rectifying, double layers coinciding, bottom film feed and inserting, (shape puncher), servo drive, spout feed, spout hot sealing, spout cold sealing, cross hot sealing, cross cold sealing, (shape puncher),color code tracking, servo traction, cutting off (shape puncher), products unloading table.

Advantage

1.Welding nozzle, bag making machine

2.Double independent bag, storage (refueling without stop)

3.Double cutting knife, double roll

Working process

The machine starts from unwinding, in turn are magnetic powder brake, dancer arm roller tension adjusting, cutting, rectifying, double layers coinciding, bottom film inserting, shape puncher, servo drive, spout feed, spout hot sealing, spout cold sealing, cross hot sealing, cross cold sealing, color code tracking, servo traction, cutting off (shape puncher), products unloading table.

Machine technique parameters

| 1 | Film material | Plastic laminated film |

| 2 | Capacity: | Single bag feed:Max35-40pcs/minDouble bag feed:Max 70-80pcs/min |

| 3 | Material thickness | 0.06~0.15mm |

| 4 | Spout type | Different kinds of small plastic spout. |

| 5 | (Speed for spout pouch, specific speed according to pouch size and material) | |

| 6 | Pouch size:(L×W) | Single bag feed:Max300×200mmDouble bag feed:Max150×100mm |

| 7 | Total power | About 25KW |

| 8 | Power voltage | AC380V,50HZ, 3P |

| 9 | Air pressure: | 0.5-0.7Mpa |

| 10 | Cooling water: | 10L/min |

| 11 | Machine working table height: | 950mm |

| handle operation height 850mm | ||

| 12 | Machine dimension(MAX): | L×W×H: 8200mm×3500mm×2000mm |

| 13 | Machine weight: | about 5000KG |

| 14 | Machine color: | Gray (wallboard)/ stainless steel (guard board) |