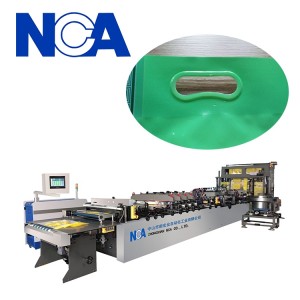

NCA1623B Automatic Pouch Spout Inserter

Usage

1.The machine is used to cut an angle and weld a plastic spout on the cut automatically.

2.It is suitable for the large pouches of drinks, chrysanthemum MSG, grape sugar powder, washing liquid, hand washing liquid and cosmetics etc.

3. Depending on the characteristics of the material, this equipment can be tailored to prevent material deformation during extrusion.

Advantage

1、Capacity:40-45pcs/min.

2、Spout type:Short spout, supplied by the customer.(φ5mm-φ25mm).

2、Mechanical sealing (4-5 servo) , and lower maintenance costs.

3、Automatic Angle cutting function, center/corner spout pouch.

4、With pouch feeding conveyor and finished pouch unloading conveyor.

List of Key Components

Control: PLC (Japan Mitsubishi)

Main drive: Servo (Japan Panasonic)

Vacuum system: Vacuum pump(Germany)

Sealing system: Mechanical(Japan Panasonic)

Pouch pick & feed: Cylinder(Japan SMC)

Spout insert: Servo(Japan Panasonic)

Specification

| Pouch size (L×W) | Corner spout: (120-320)×(100-250)mmMAX: 300×250mm 320×200mm 260×260mm |

| Cutting angle | 17º---45º±2º |

| Spout type | Short spout, supplied by the customer.(φ5mm-φ25mm) |

| Production efficiency | 40-45 pieces/min(the smaller size pouch)35-40 pieces/min(the bigger size pouch)Note: The production efficiency varies because of the material and the difference of the pouch size. |

| Power | AC380V,50HZ,11KW,3P |

| Compressed air | 0.7Mpa, 250NL/min |

| Dimension (L×W×H) | 5700×3000×1900mm |

| Cooling water | 6L/min |

| Weight | 2000Kg |