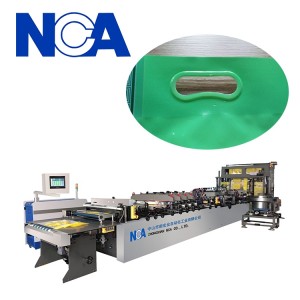

NCA1623 Automatic Pouch Spout Inserter

Usage

1.The machine is used to cut an angle and weld a plastic spout on the cut automatically.

2.It is suitable for the large pouches of drinks, chrysanthemum MSG, grape sugar powder, washing liquid, hand washing liquid and cosmetics etc.

3. Computer-controlled, touch-screen display with Mandarin and English, printing capability, and automated alert for ribbon exhaustion. 304 food-grade stainless steel. Drop material detection, which prevents heat sealing when there is no material inside the bag, helps to reduce bag waste.

4. Practical layout, compact size, easy operation. You are welcome to view all objects because they have the required credentials.

5. Depending on the characteristics of the material, this equipment can be tailored to prevent material deformation during extrusion.

6. It might feature low energy consumption, multiple-stage frequency conversion speed control, high precision control, and stable operation.

7. You can also contact us directly if you need customized products.

8. Promote free proofreading to help various economic industries acquire package intelligence.

Advantage

1、Capacity:35-40pcs/min.

2、Spout type:Short spout, supplied by the customer.(φ5mm-φ25mm).

3、Mechanical sealing (4-5 servo)

4、Automatic Angle cutting function,for both center spout pouch & corner spout pouch.

Specification

| Pouch size (L×W) | Corner spout: (120-320)×(100-250)mmMAX: 300×250mm 320×200mm 260×260mm |

| Cutting angle | 17º---45º±2º |

| Spout type | Short spout, supplied by the customer.(φ5mm-φ25mm) |

| Production efficiency | 35-40 pieces/min(the smaller size pouch)30-35 pieces/min(the bigger size pouch)Note: The production efficiency varies because of the material and the difference of the pouch size. |

| Power | AC380V,50HZ,5.5KW,3P |

| Compressed air | 0.7Mpa, 250NL/min |

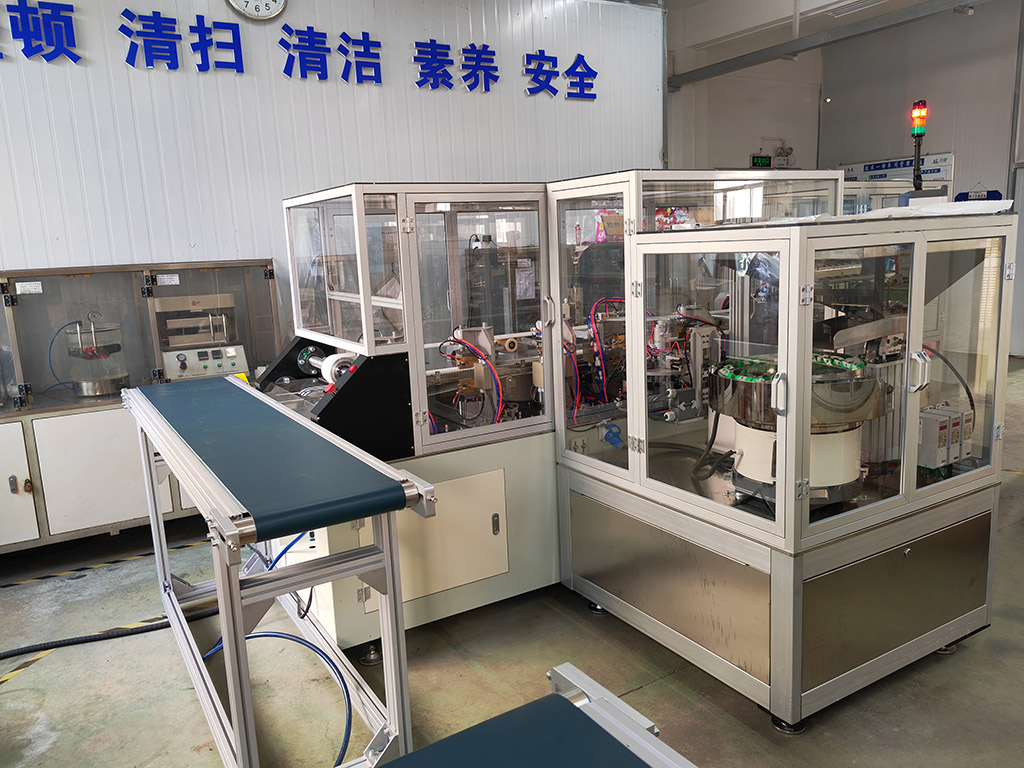

| Dimension (L×W×H) | 4210×1900×1910mm |

| Cooling water | 6L/min |

| Weight | 1800Kg |