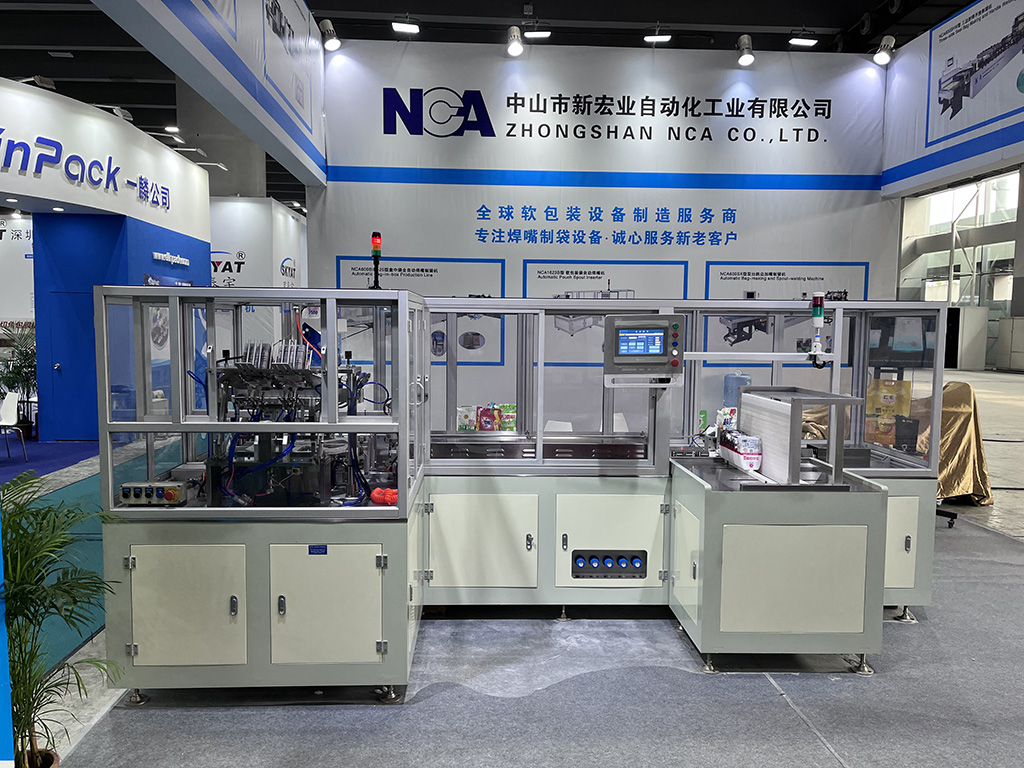

NCA1604D-90 Flexible Pouch and Spout Automatic Sealing Machine

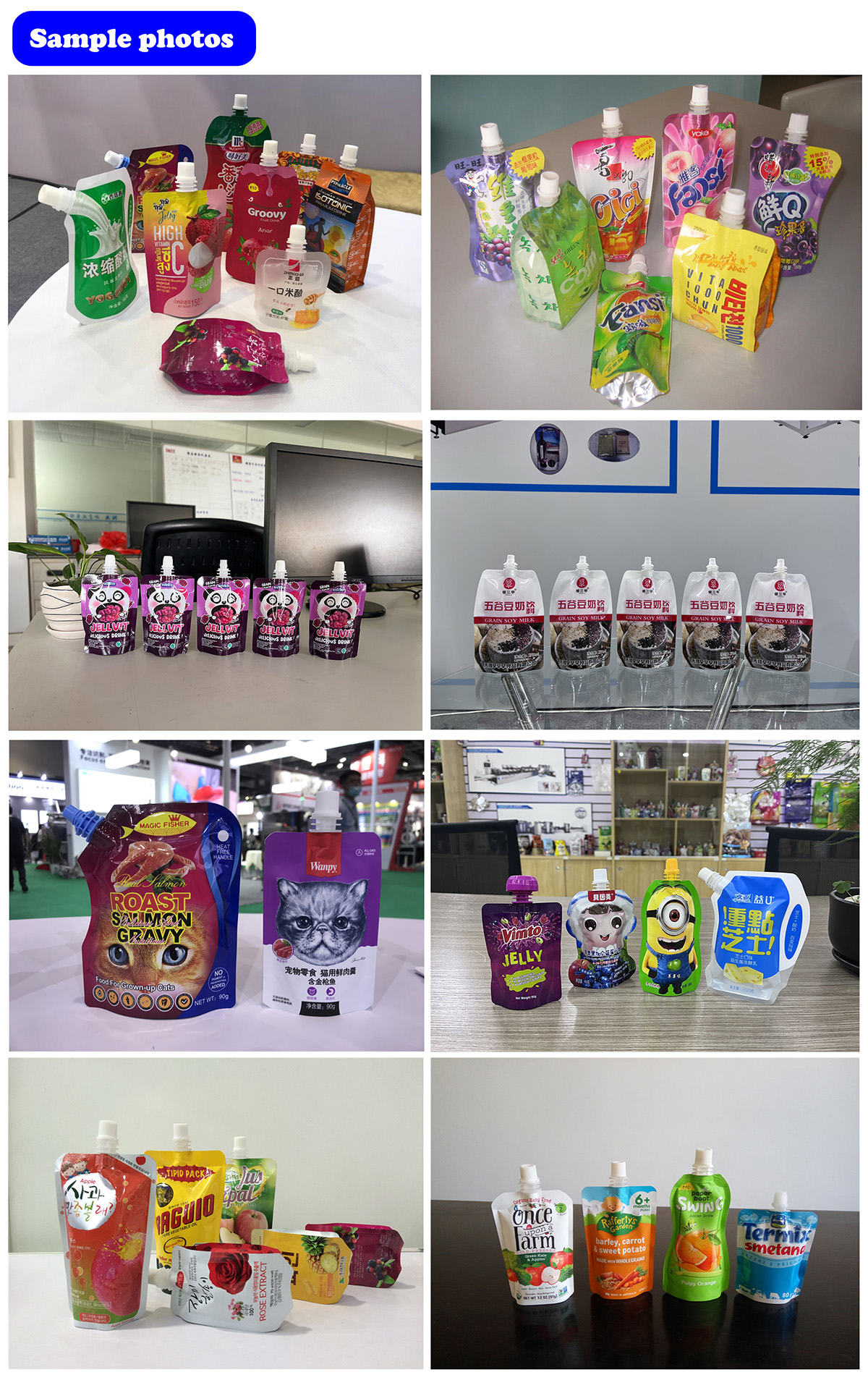

Usage

l.The machine is used to weld a plastic spout to a flexible pouch.

2.It is suitable for packaging drinks, jelly, soy sauce, flavorings and cosmetics (milk, face mask) etc..

Advantage

1、Mechanical sealing (3 servo); Small noise; Low gas consumption

2、Various function:center/corner spout pouch; speed 80-90 pcs/min

3、Upgraded safety protective cover,One-man operation

4、Upgraded safety protective cover

5、Pouch holder design positional precisely

6、New pouch put way,easier to adjust more stable

Main Technical Specification

|

Pouch size (L×W) |

Center spout pouch (100-190)× (70-120)mm (Different pouch size needs to adjust or change the pouch tank adjusting board.) |

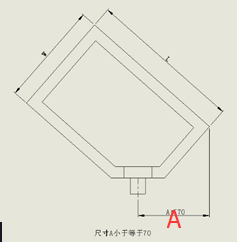

| Corner spout pouch (100-160)×(70-110)mm

(Different pouch size needs to change the pouch tank, accompanying frame etc.) Max angle 45 degree Size A≦ 70mm Note: the machine is with corner spout function, if need to do corner spout bag, only add the pouch tank and accompanying frame extra. |

|

| Spout type | Long or short spout with the bayonet, supplied by the customer. |

| Production efficiency | Center spout pouch: 85-90pcs/min

Corner spout pouch: 80-85pcs/min Note: The production efficiency varies because of the material and the difference of the pouch size. |

| Power | AC380V,50HZ,9.5KW,3P |

| Compressed air | 0.6-0.8Mpa, 360NL/min |

| Dimension (L×W×H) | 4250×1900×1730mm |

| Cooling water | 6L/min |

| Weight | 2600Kg |