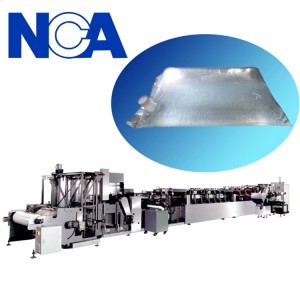

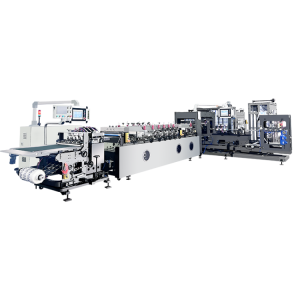

NCA1604A-90 Flexible Pouch and Spout Automatic Sealing Machine

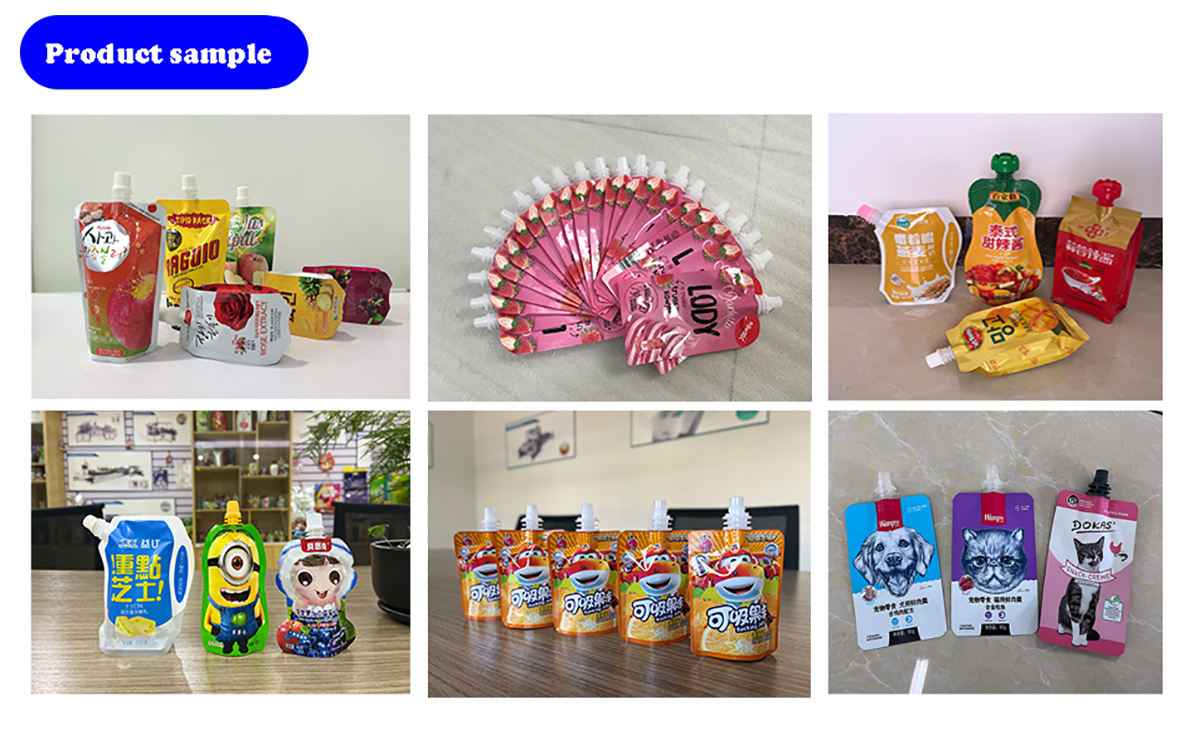

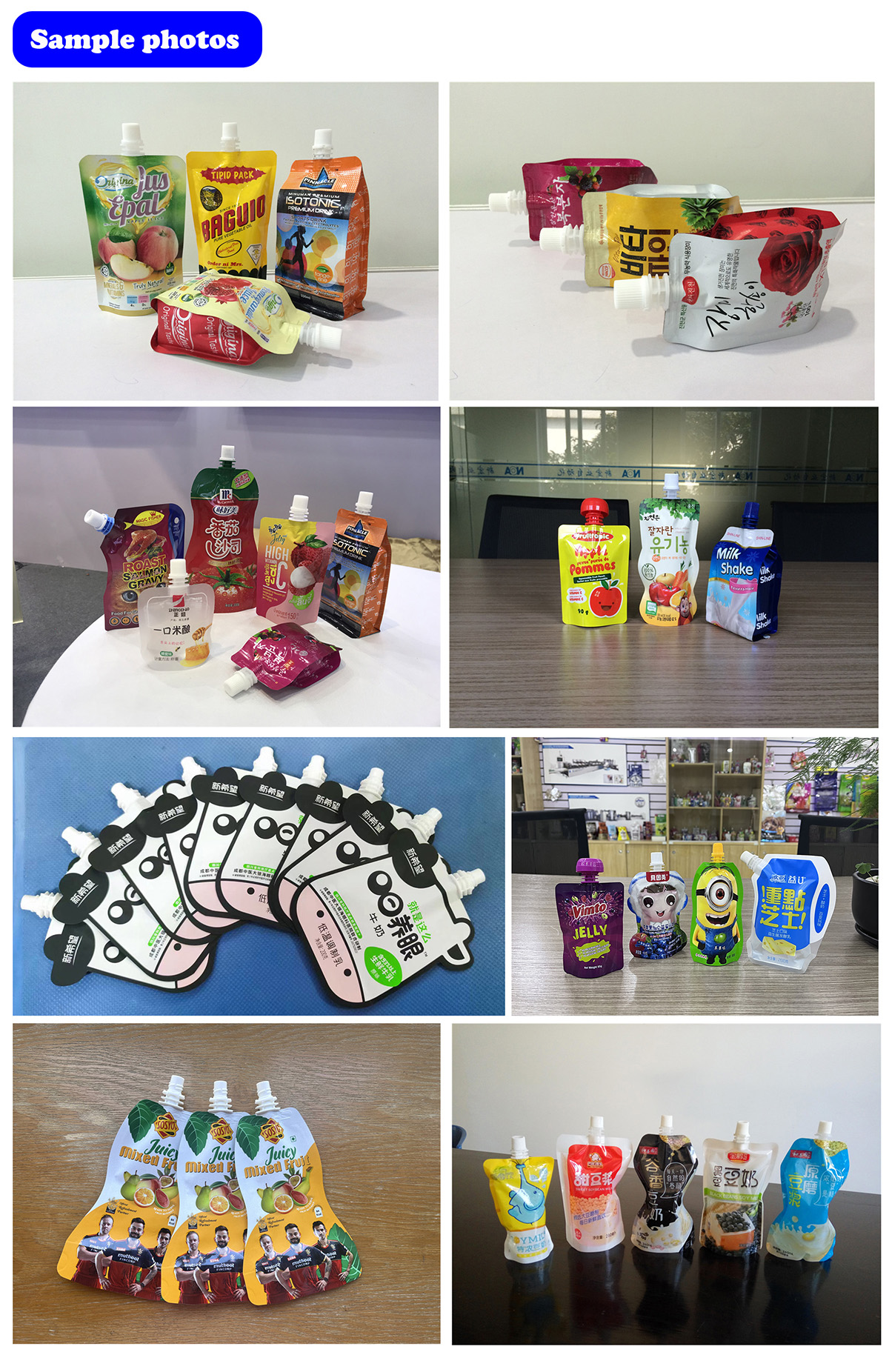

Usage

1. The machine is used to weld a plastic spout to a flexible pouch.

2. It is suitable for packaging drinks, jelly, soy sauce, flavorings and cosmetics (milk, face mask) etc..

Advantage

1、Mechanical sealing (3 servo); Small noise; Low gas consumption

2、Various function:center/corner spout pouch; speed 80-90 pcs/min

3、Upgraded safety protective cover,One-man operation

4、Upgraded safety protective cover

5、Pouch holder design positional precisely

6、New pouch put way,easier to adjust more stable

ore stable

The price is including the cost of the wooden packing, fumigation quarantine inspection, apply for custom(export), but not including sea freight and transport charge for machine to the position.

Main Technical Specification

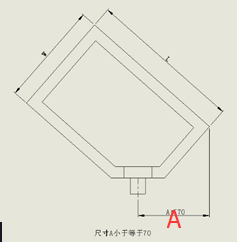

| Pouch size (L×W) | Center spout pouch (100-190)× (70-120)mm (Different pouch size needs to adjust or change the pouch tank adjusting board.) |

| Corner spout pouch (100-160)×(70-110)mm(Different pouch size needs to change the pouch tank, accompanying frame etc.)

Max angle 45 degree Size A≦ 70mm Note: the machine is with corner spout function, if need to do corner spout bag, only add the pouch tank and accompanying frame extra. |

|

| Spout type | Long or short spout with the bayonet, supplied by the customer. |

| Production efficiency | Center spout pouch: 85-90pcs/minCorner spout pouch: 80-85pcs/min

Note: The production efficiency varies because of the material and the difference of the pouch size. |

| Power | AC380V,50HZ,9.5KW,3P |

| Compressed air | 0.6-0.8Mpa, 360NL/min |

| Dimension (L×W×H) | 4200×2400×1960mm |

| Cooling water | 6L/min |

| Weight | 2600Kg |